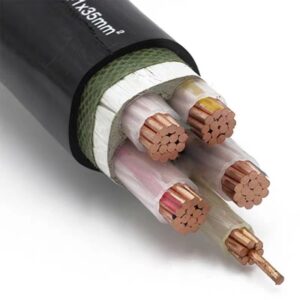

When selecting power cables for industrial, commercial, or infrastructure projects, understanding the differences between high voltage cables (1kV–1000kV) and low voltage cables (below 1kV) is crucial. These two cable types serve distinct purposes in power transmission and distribution, with variations in construction, safety standards, and applications. In this guide, we’ll compare their key characteristics, helping engineers, procurement specialists, and project managers make informed decisions. 1. Voltage Classifications: What Defines High & Low Voltage? High Voltage Cables (HV) Low Voltage Cables (LV) 2. Construction Differences Feature High Voltage Cables Low Voltage Cables Conductor Copper or aluminum (stranded for flexibility) Copper or aluminum (solid or stranded) Insulation XLPE, EPR, or oil-impregnated paper PVC, rubber, or thermoplastic

THHN vs. THWN Wire: Understanding the Differences for Electrical Applications When selecting electrical wiring for industrial, commercial, or residential projects, understanding the specifications of different wire types is critical for safety, compliance, and performance. Two commonly used wire types are THHN and THWN, which share similarities but have distinct differences in their capabilities. Below, we break down their characteristics, applications, and key considerations to help you choose the right option for your needs. What is THHN Wire? Common Applications: What is THWN Wire? Common Applications: Key Differences Between THHN and THWN Feature THHN THWN Water Resistance Not rated for submersion. Suitable for wet locations. Temperature Range 90°C (dry) only. 75°C (wet) / 90°C

1. Material Composition and Structural DesignSolar Cable (PV Cable)Conductor: 1.Oxygen-Free Copper (OFC): ≥99.99% purity, minimizing resistance and electron scattering. Cross-sectional areas (e.g., 4mm², 6mm²) are optimized for DC current flow, reducing energy loss to <1% over long distances.2.Tinning Option: Some PV cables feature tin-plated copper to prevent oxidation in humid environments.Insulation: 1.Inner Layer: Cross-linked polyolefin (XLPO), a thermoset material resistant to cracking at high temperatures (up to 120°C).2.Outer Layer: High-density polyethylene (HDPE) or LSZH (Low Smoke Zero Halogen), providing mechanical protection against abrasion and UV degradation.Sheath: 1.LSZH Material: Halogen-free, emitting minimal smoke and no toxic gases (e.g., dioxins) during combustion. Passes IEC 60754-1/2 for gas toxicity testing.Normal Cable (e.g., PVC

In our modern, technology-driven world, cables are the unsung heroes that power and connect our devices. Selecting the right cable is crucial for ensuring optimal performance, safety, and durability. Here are some key factors to consider when making your choice. Purpose and Application The first step in choosing a cable is to determine its intended use. Different applications require different types of cables. For example, if you need to connect a computer to a monitor, you’ll likely need an HDMI or DisplayPort cable. For charging your mobile device, a USB cable is the way to go. Industrial applications may demand cables with higher resistance to heat, chemicals, and physical stress.

When it comes to choosing a cable manufacturer, several crucial factors need to be considered to ensure you get high-quality products and reliable services. First and foremost, product quality is of utmost importance. A reputable cable manufacturer should adhere to strict international and national standards. Check if the manufacturer has relevant certifications, such as ISO 9001 for quality management systems. These certifications are indicators that the company follows rigorous production processes, from raw material sourcing to the final product inspection. High-quality cables are made from premium materials, which ensure durability, excellent conductivity, and resistance to environmental factors like moisture, heat, and chemicals. Secondly, consider the manufacturer’s experience and expertise. An

In the power system, cable accessories as an important part of the cable system, its quality and performance are directly related to the safety and reliability of the whole cable system. Choosing the right cable accessory material not only improves the operational efficiency of the cable system, but also extends the service life of the cable and reduces maintenance costs. In the power system, cable accessories as an important part of the cable system, its quality and performance are directly related to the safety and reliability of the entire cable system. Choosing the right cable accessory material not only improves the operational efficiency of the cable system, but also extends

© All Rights Reserved.