TC-ER cable product introduction

1.Main Features

(1)Excellent electrical performance: TC-ER cables have excellent electrical conductivity and insulation properties, which can ensure stable transmission of power and signals.

(2)High heat resistance: the cable is rated up to 90°C, which is suitable for power and signal transmission in high temperature environments.

(3)Anti-electromagnetic interference: TC-ER cable adopts special shielding design, which can effectively resist electromagnetic interference and ensure accurate signal transmission.

(4)Wear-resistant and stretch-resistant: The outer sheath of the cable is made of wear-resistant material, which is able to resist mechanical wear and stretch and prolong its service life.

(5)Environmental performance: some TC-ER cables are made of low-smoke halogen-free materials, which meets the requirements of environmental protection and does not produce toxic gases when burning.

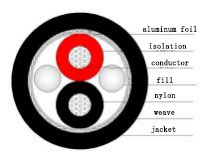

2.Main Structure

(1)Conductor: The conductor of TC-ER cables usually adopts stranded tinned copper wire, which has good electrical conductivity and mechanical strength.

(2)Insulation: The insulation layer is made of cross-linked polyethylene (XLPE) or polyethylene (PE) with high insulation resistance and excellent heat resistance.

(3)Shielding: Optional aluminum foil shielding and copper braid shielding are used to improve the cable’s resistance to electromagnetic interference.

(4)Outer jacket: Outer jacket materials including polyvinyl chloride (PVC), low-smoke, no-halogen (LSZH) or nylon provide additional mechanical protection and abrasion resistance.

Executive Standards

TC-ER cables implement UL1277 standard, which covers cable construction, performance requirements, test methods, etc. to ensure the quality and safety of cables.

TC-ER cable product applications

1.Industrial automation and control systems

TC-ER cables are widely used in industrial automation and control systems, connecting various sensors, actuators, controllers and other equipment to realize automation control and remote monitoring.

2.Power Distribution and Transmission Systems

In power distribution and transmission systems, TC-ER cables are used to transmit power and ensure the stable operation of the power system.

3.Instrumentation and Measuring Devices

TC-ER cables are suitable for various meters and measuring equipment, such as ammeters, voltmeters, power meters, etc., to ensure the accuracy and reliability of measurement results.

4.Power and control systems inside buildings

Inside buildings, TC-ER cables are used to connect various electrical equipment, such as lighting equipment, air conditioning equipment, elevator equipment, etc., to achieve stable transmission of power and signals.

5.Wind Power Generation

TC-ER cables are also suitable for wind power generation, installed inside wind turbines and laid through cable trays or piping to ensure stable transmission of power and signals.

© All Rights Reserved.