Product Overview

Engineered for extreme mining environments, our mining cable delivers unmatched durability, safety, and performance in underground and surface operations. With triple-layer shielding, -40°C to 90°C temperature resistance, and MSHA/UL certifications, it powers haul trucks, drills, and conveyors while resisting abrasion, chemicals, and impact.

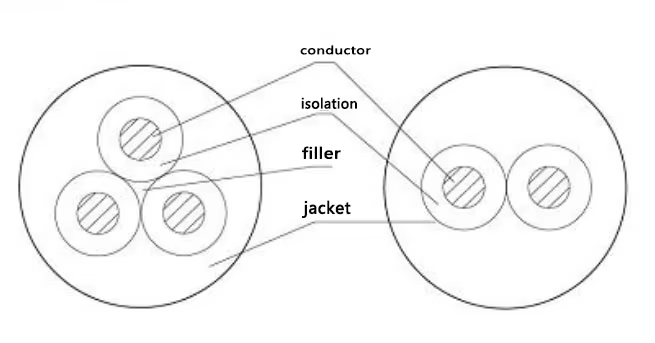

Conductor: Oxygen-free tinned copper (Class 5 flexibility)

Insulation: EPR (Ethylene Propylene Rubber) for heat/oil resistance

Jacket: CSP (Chlorosulfonated Polyethylene) – resists UV, chemicals, and tearing

Shielding: Braided copper + aluminum foil + grounding drain wire (triple EMI protection)

MSHA 30 CFR Part 18 Certified: Explosion-proof for hazardous underground zones

UL 1277 Listed: Meals flame-retardant requirements

IEC 60502-2 Compliant: Global mining safety standard

| Parameter | Specification |

|---|---|

| Voltage Rating | 600V–2000V |

| Temperature | -40°C to +90°C |

| Bending Radius | 6× cable diameter |

| Conductor Sizes | 6 AWG to 500 MCM |

Ideal for:

✅ Shuttle Cars & Haul Trucks

✅ Draglines & Drilling Rigs

✅ Conveyor Systems & Hoists

✅ Explosive Environments (Zone 1/2)

Standard cables fail quickly in mining due to:

❌ Abrasion from rocks/equipment

❌ Oil/grease degradation

❌ Voltage spikes causing fires

Extended Flex Life: 1M+ bend cycles (tested per ICEA S-75-381)

Oil Resistance: Passes UL 1277 Oil Immersion Test (168 hrs @ 100°C)

Flame Retardancy: Self-extinguishing per UL 1581 VW-1

Bending: Minimum radius = 6× cable diameter

Termination: Use MSHA-approved connectors (e.g., Eaton Cutler-Hammer)

Maintenance: Inspect every 500 hrs for jacket abrasion

⚠️ Warning: Non-MSHA cables risk explosions in gassy mines!

MSHA 30 CFR Part 18 (US Mine Safety)

UL 1277 (Flame Resistance)

IEC 60502-2 (International Mining Cables)

CAN/CSA C22.2 No. 96 (Canadian Standards)

© Todos Los Derechos Reservados.