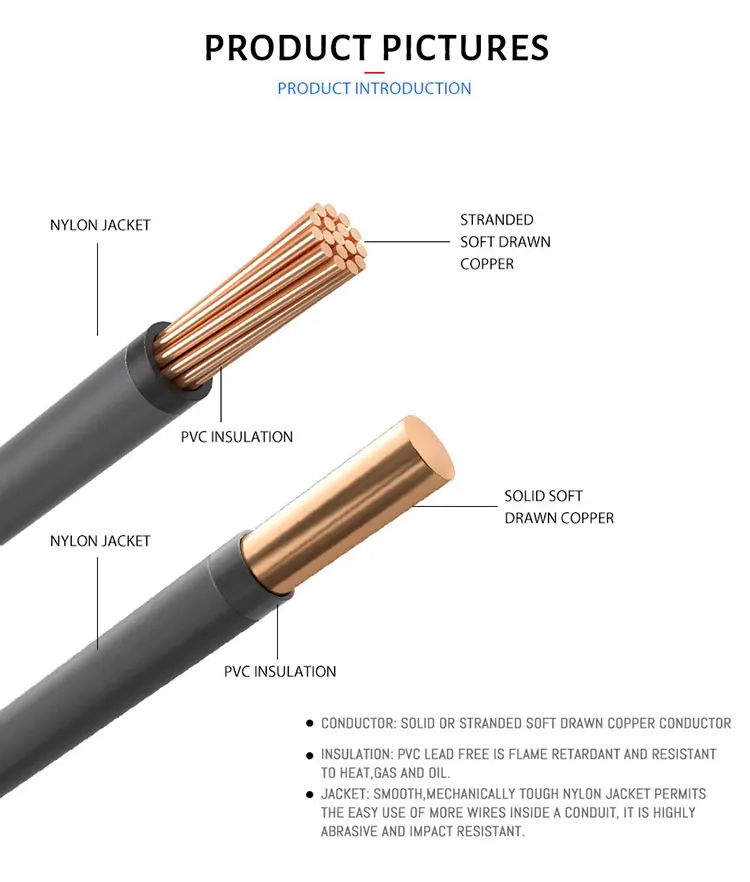

I. Basic Definition and Characteristics of THHN Wire

THHN Wire, full name is Thermoplastic High Heat-resistant Nylon coated Wire. This wire stands out for its unique thermoplasticity and high heat-resistant properties.THHN wire is usually made of one or more fine copper wires stranded together and covered with a thermoplastic high heat-resistant nylon jacket, which has good insulating properties and abrasion resistance.

The main characteristics of THHN wire include:

1. high heat resistance: it can maintain stable electrical performance in higher temperature environments, and can usually withstand temperatures as high as 150°C to 200°C. 2. good electrical performance: it has the ability to withstand temperatures as high as 150°C to 200°C, and can be used in a variety of applications.

2. good electrical properties: excellent electrical conductivity and insulation properties, which can effectively reduce power loss and improve the safety of electrical systems.

3. Strong abrasion resistance: The outer nylon sheath has good abrasion resistance and protects the internal copper wires from external physical damage.

4. Good flexibility: THHN wire has good flexibility, which is easy for installation and wiring.

|

MM2

|

AWG/kcmil

|

Diameter of

|

Min.No

|

Insulation

|

JACKET

|

Diam.

|

Approx.

|

NEC

|

|

|

conductor

|

of wire

|

Thickness

|

THICKNESS

|

Wt.

|

|||||

|

–

|

–

|

–

|

mm

|

n

|

mm

|

mm

|

mm

|

Kg/km

|

Ampacity

|

|

2.08

|

14

|

AWG

|

1.85

|

7

|

0.38

|

0.1

|

2.8

|

25

|

20

|

|

3.31

|

12

|

AWG

|

2.32

|

7

|

0.38

|

0.1

|

3.3

|

37

|

25

|

|

5.26

|

10

|

AWG

|

2.95

|

7

|

0.51

|

0.1

|

4.2

|

59

|

35

|

|

8.37

|

8

|

AWG

|

3.71

|

7

|

0.76

|

0.13

|

5.5

|

96

|

50

|

|

13.3

|

6

|

AWG

|

4.67

|

7

|

0.76

|

0.13

|

6.5

|

145

|

65

|

|

21.2

|

4

|

AWG

|

5.89

|

7

|

1.02

|

0.15

|

8.2

|

232

|

85

|

|

26.7

|

3

|

AWG

|

6.6

|

7

|

1.02

|

0.15

|

8.9

|

285

|

100

|

|

33.6

|

2

|

AWG

|

7.42

|

7

|

1.02

|

0.15

|

9.8

|

352

|

115

|

|

42.4

|

1

|

AWG

|

8.43

|

19

|

1.27

|

0.18

|

11.3

|

452

|

130

|

|

53.5

|

1/0

|

AWG

|

9.45

|

19

|

1.27

|

0.18

|

12.4

|

559

|

150

|

|

67.4

|

2/0

|

AWG

|

10.62

|

19

|

1.27

|

0.18

|

13.5

|

692

|

175

|

|

85

|

3/0

|

AWG

|

11.94

|

19

|

1.27

|

0.18

|

14.8

|

860

|

200

|

|

107

|

4/0

|

AWG

|

13.41

|

19

|

1.27

|

0.18

|

16.3

|

1068

|

230

|

|

127

|

250

|

kcmil

|

14.6

|

37

|

1.52

|

0.2

|

18

|

1279

|

255

|

|

152

|

300

|

kcmil

|

16

|

37

|

1.52

|

0.2

|

19.4

|

1516

|

285

|

|

177

|

350

|

kcmil

|

17.3

|

37

|

1.52

|

0.2

|

20.7

|

1751

|

310

|

|

203

|

400

|

kcmil

|

18.49

|

37

|

1.52

|

0.2

|

21.9

|

1995

|

335

|

|

228

|

450

|

kcmil

|

19.61

|

37

|

1.52

|

0.2

|

23.1

|

2229

|

380

|

|

253

|

500

|

kcmil

|

20.65

|

37

|

1.52

|

0.2

|

24.1

|

2463

|

420

|

II.Application Scenarios of THHN Wire

Due to its excellent performance and wide applicability, THHN Wire is widely used in building, industrial and household electrical systems. For example, in high-rise buildings, THHN Wire can be used for wiring electrical equipment such as switchboards, lighting equipment and air-conditioning systems; in industrial production lines, it can be used for connecting electric motors, control equipment and instrumentation; and in home environments, THHN Wire can be used for wiring sockets, switches and lighting fixtures.

© Все права Защищены.